The problem

The buses that are in use for commercial passenger transport, particularly labour and school buses have two Diesel engines: a large one for moving the bus, and on the picture shown above, the smaller one, which is driving the air conditioner. This engine is not only loud and oversized for its purpose, but it also consumes a lot of fuel. Worst of all, the exhaust fumes – with all their small-partcile soot, carcinogens, NOx-es – are released into the environment without any filtering.

…and as you can see from this Google Maps satellite image above, there are lot of these buses around! And all of them have these engines, and all of them release their fumes – which all of us breathe in.

Our solution

We decided to throw that small Diesel engine out, fit solar panels on the roof of the bus, and use an electric motor to drive the air conditioner’s compressor.

But the sun doesn’t always shine…

For this reason, we made the air conditioner run from a battery as well. Since we know how these buses are used in each working day, we made sure that the air conditioner can work from the battery for about an hour. All we have to do is to ask the driver to park the bus under the sun, and the batteries will be charged. Should that prove insufficient, the bus can be charged using the mains electrical grid as well. No special charger or adapter is needed:

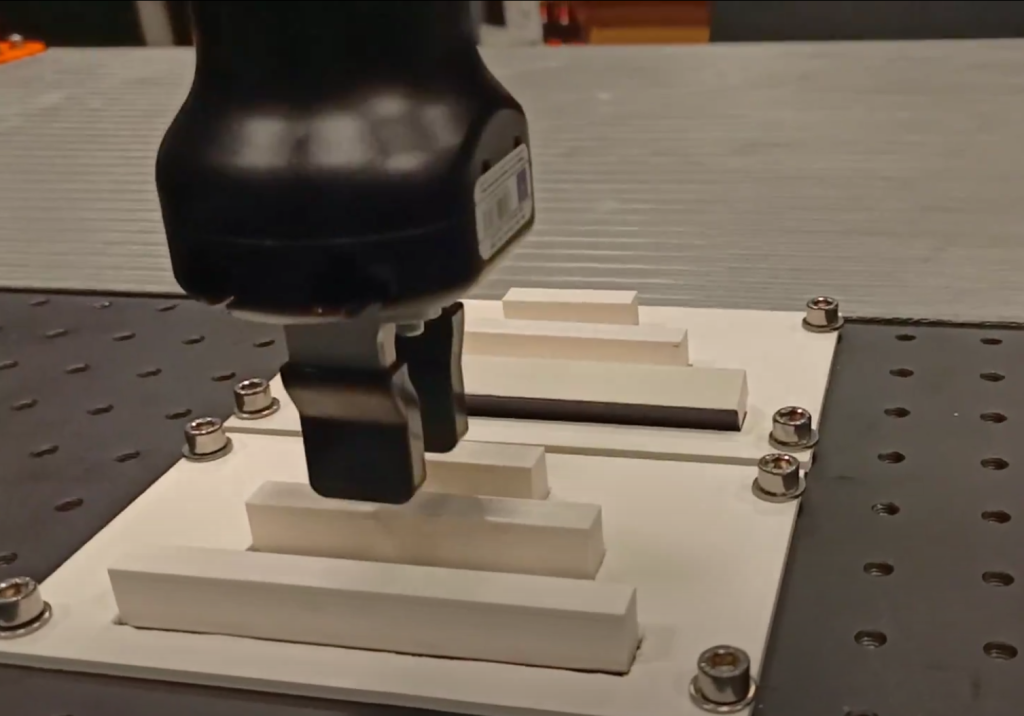

This is a working prototype

We are testing this as we go, and learning more by the day.

So far, the results look promising, as we found a way to optimise the thermal efficiency of the system. We were genuinely surprised how wasteful that Diesel engine was. As a plus, the bus is now quieter, cheaper to run, and there are no fumes from running the air conditioning!

We prepared a couple of documents that introduce our prototpye system. This is the result from a year’s worth of weekends of applied research and development. In particular see the:

- White paper,

which explains how the system works, its intended usage pattern, and how much carbon emission can be saved; and what are the running costs. - Calculator spreadsheet,

where we demonstrate how we calculated the numbers we wrote in the white paper. - Questions and answers,

we have been asked many questions before, so we collected the most common ones here. - References and further reading,

where we show where we got our information from.

We’d like to thank the following people for their help (in no particular order)

- Matthew Karau, for the valuable input

- Alex Avdeev, for the discussion about some mechanical parts

- Nelson Reyes, for welding tuition

- Sunil Kumar, for some refrigeration equipment

- Vijay Dhanvi, for some CNC and waterjet cutter work

- Jorge Navarette, for additional mechanical tuition and work

- Michael Shiloh, for additional input